| By: Paul S. Cilwa | Viewed: 4/17/2024 Occurred: 10/13/2020 |

Page Views: 684 | |

| Topics: #Coronavirus #Maui | |||

| While isolated during a pandemic, is the perfect time for construction projects. | |||

I don't have a lot of experience doing woodworking, but I've been thinking for several weeks now about how to create a platform bed out of scrap lumber we have, to replace the awkward mattress-on-two-cots contraption we were using. And today, with help from my husband, we made it a reality.

But first, let me describe the contraption. (Sorry, there are no pictures.)

When we first moved to the shed, Keith and I used a queen-sized camping mattress. But it developed a leak and had to be replaced after a month or so. And a month later, the replacement also developed a leak.

Apparently, the makers of camping equipment don't really expect their customers to use their products for extended periods.

So we bought a regular, queen-sized, memory-foam, mattress.

At first we just put it on the floor. But I hated having to get up and down from it, plus it made it easier for the critters with which we share the shed (like centipedes and earwigs) to also share our bed. So I took two camp cots that were on the property and brought them to the shed to put the mattress on. The cots were two narrow to support the mattress if they were directly adjacent; so I separated them with flagstones I brought in.

That supported the mattress and brought it off the floor. But the cots tended to scoot apart. So I had to add bungee cords to keep the cots as close together as the flagstones would allow.

But then one set of legs on one cot started bending, making one corner of the mattress sink toward the flo or.

I considered simply buying an assemble-it-yourself platform bed from Walmart. But 1) I didn't have a spare $100 to buy one; and 2) I knew from experience that, once assembled, it would be too flimsy to move, as we'll have to do if and when our bamboo hut is finally completed.

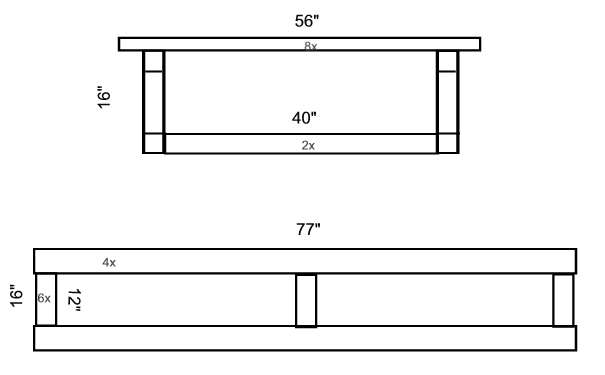

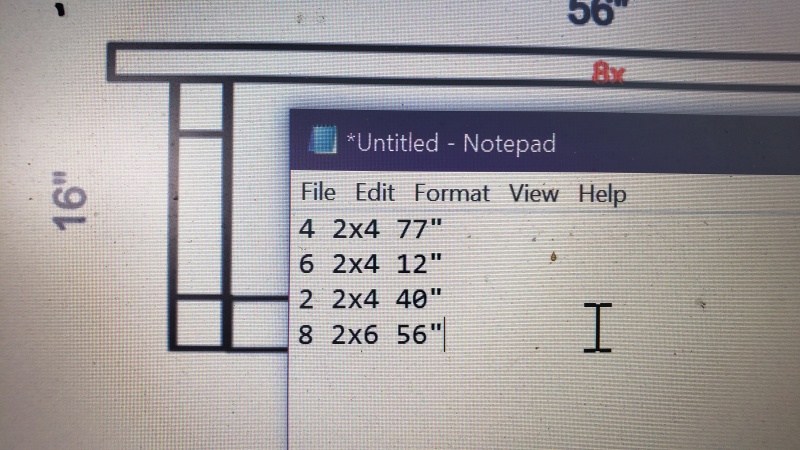

So the next option was to build something. I wanted something practical, sturdy, moveable, and cheap (preferably, free). I decided on a design of two rectangles for the sides, held together by planks on the bottom and slats on the top. The mattress is intended to overhang the slats by a couple of inches. This design allows for storage under the bed, and also makes it difficult for critters to climb up and under to get to the top of the mattress. And, last but not least, it gives our dog Lilly a replacement for her chosen den beneath the cots.

I got the measurements for a standard queen mattress and bed height from the Internet. That allowed me to calculate the sizes to cut the boards.

I measured and cut the boards.

Then Keith did the hammering; and in no time we had the two side support rectangles.

We stood the mattress on end and removed the cots, bungee cords and flagstones, and cleaned the floor where they'd been. We then stood the support rectangle in place.

The only things I had to buy for this project were metal corner braces and a few wood screws.

Recessing the horizontal supports makes for better distribution of stresses.

The top of the bed is its slats. A typical platform bed would have a solid top. But memory foam mattresses have stiff bottoms, making them easily sturdy enough to be supported by slats a few inches apart. This also allows the mattress to breathe, minimizing the chances of fungal growth.

Once down, positioning the mattress and putting lines on the bed was a simple matter.

And Lilly immediately took up position beneath the bed, as if nothing had changed.

Except now, she doesn't have to worry about being squashed if Keith or I get on the bed while she's down there!

P.S.: There's nothing more satisfying than sleeping on a bed you've actually constructed yourself.